Services we offer

Sheet Metal Profiling

1 x Esprit Viper HD Plasma (3m x 10m sheet area)

1 X RUR 3000 Plasma (2.5m x 8m Sheet Area)

Capacity of piercing and profiling up to 70mm thick mild steel

Metal Forming

Durma 40320 Tandem Press brake with a 4m x 320 Ton folding capacity (Singular). When in Tandem capacity is 8.6m x 640 ton to 15mm thick plate. Our fully trained and experienced operators have over thirty years’ experience in operation of presses.

We have recently invested in a Sahinler Tube Bending machine with a bend capability of up to ø60 x 4mm wall thickness.

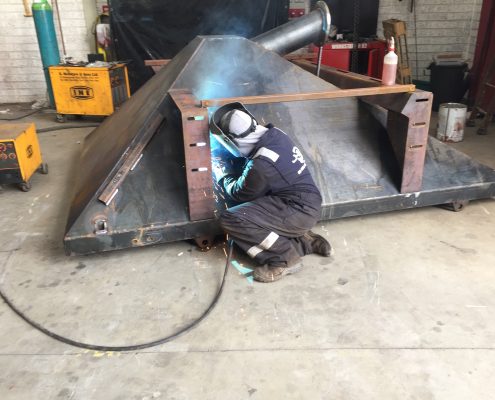

Fabrication & Welding

We have built a new state of the art 1080 M2 floor area, purpose built fabrication and welding facility with a 10000Kg SWL overhead gantry crane servicing 21 weld bays each with their own 500Kg SWL swing Jib crane. Each bay has its own fleet of serviced lifting equipment and tools as well as calibrated INE Weld Sets. We have our own weld procedures based on Industry requirements and have a range of welding personnel trained & tested to these procedures. We also have the services of conducting a range of Non-Destructive testing on our welds to suit Customer requirements.

We offer mild steel welding of a range of equipment such as Conveyors, Structural Steelwork, Chassis, Tanks, Chutes, Hoppers, Walkways, Stairs, Handrailing, access equipment & Pipework.

Surface preparation

We offer a shot blasting service to SA 2.5 (Minimum) to BS 7079:2009. Our shot blast facility consists of 133m2 floor area. Garnet grit is used as our blast medium.

After blasting the application of a sealant between stitch welds can be applied as per customer requirements.

We also carry out the service of rubber lining to various thicknesses as per customer requirements.

Surface Coating

We have 2 No. ventilated spray painting booths each consists of 190m2.floor area. We use Graco Airless sprayer system and have experience in all RAL colours and paint manufacturers such as International, Becker’s, PPG, Spencer, Jotun. We also have the services available for Galvanising to BS EN ISO 1461:2009 and Powder Coating to BS EN 12206-1:2004 / BS 13438:2005

Assembly & Delivery

We have a dedicated assembly facility where our assembly engineers can fit and build our manufactured and finished plant and equipment as per specification and customer requirements. We can pack and deliver your product on our own fleet consisting of 40’ and 20’ Fully PSV’d Flatbed lorries.